Colour changing freshness sensor for meats uses nanocellulose and vegetable dyes | 30-05-2024 |

Patches that change colour as raw meat freshness deteriorates in sealed refrigerated products is not a new concept, as several companies are now offering colour changing sensors for proteins. This includes AIPIA members, AIMPLAS and Senoptica. And Auburn University in USA has recently patented a colour changing sensor for meats, as AIPIA reported in April. The latest version has been developed by Monash University in Melbourne, Australia, where researchers are using on-pack colour indicators made from natural plant materials to show how fresh the beef is in real-time and could be used to replace traditional ‘Best Before’ dates.

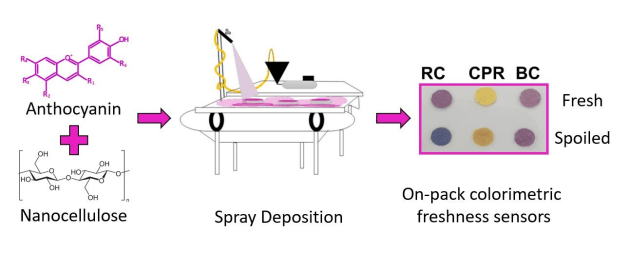

The researchers, led by former Monash University PhD student Debarati Bhadury (now at the University of Washington in Seattle), believe their method could reduce the amount of meat thrown away when it's still safe to eat. Using beef porterhouse steaks, the research demonstrated that when applied to the inside of transparent packaging film, the indicators consistently changed colour in response to rising pH levels caused by growth of bacteria, such as E. coli.

Machine-readable versions could also become a possibility, helping to automate aspects of the supply chain and retailing, such as price discounting as freshness changes, and the technology is also likely to be extensible to other fresh foods, says the team.

The patches, co-developed by Dr Joanne Tanner of the Department of Chemical and Biological Engineering at Monash, who supervised the research with Professor Kellie Tuck of the School of Chemistry, were made from a combination of nanocellulose and dyes found in vegetables like red cabbage and black carrot.

A ‘Best Before’ date merely represents a conservative estimate of how long the packaged meat will remain usable and is not an actual gauge of freshness. It is based on a series of worst-case assumptions about its handling and refrigeration through the supply chain, which means meat is often returned or disposed of when it is actually still fit for consumption, according to Tanner. The colour indicator system could also be linked through smartphone apps to provide consumer advice, suggesting optimal ways to cook and prepare meat based on freshness, she believes.

“Smartphone integration providing advice on food preparation is a real possibility using this freshness indicator. For example, the meat could still be consumed but should be cooked for a longer period rather than eaten rare,” Tanner added.

The study also showed that bacterial counts differed on steaks with the same ‘Best Before’ date, further highlighting the value of an on-pack indicator. According to Tanner, a combination of two or more colour-changing sensors was likely to be best for consumer use, as it would account for individual differences in colour vision.

Next steps in the research program will be to extend the findings by investigating a number of other anthocyanins that show colour changes across different pH ranges and may be suitable for different fresh foods.

AIPIA comment: A wider adoption of this kind of technology is overdue. So whichever company’s sensor is applied we hope to see more of them in the supermarkets (as well as the necessary explanation to consumers of the technology and how it works) really soon. From a B2B perspective it also has to be a cost effective solution – as well as not affecting the recycling of the material.

AWA and AIPIA Smart Labeling Chicago

AIPIA and AWA Smart Packaging World Congress Amsterdam